Difference Between Hastelloy C22 and C276

The key difference between Hastelloy C22 and C276 is their applications due to their different chemical compositions. The Hastelloy C22 is very important due to its enhanced versatility and exceptional resistance to chloride-induced pitting whereas the Hastelloy C276 is very important due to its proven performance in a wide range of aggressive chemicals.

Hastelloy C22 and C276 are nickel-chromium-molybdenum materials, which we name as alloys. They have different chemical compositions, and thus, they are useful in different applications. For example, as the chromium content of Hastelloy C22 is higher than Hastelloy C276, the Hastelloy C276 is highly resistant to oxidizing media.

CONTENTS

1. Overview and Key Difference

2. What is Hastelloy C22

3. What is Hastelloy C276

4. Side by Side Comparison – Hastelloy C22 vs C276 in Tabular Form

5. Summary

What is Hastelloy C22?

Hastelloy C22 is an alloy consisting mainly of nickel, chromium and molybdenum. As its chief important features, this alloy is resistant to both oxidizing and non-oxidizing chemicals. It provides other materials with the protection from pitting, especially, chloride-induced pitting. For example, it provides protection from chloride-induced pitting that is an unpredictable form of attack to which stainless steel is prone. Moreover, it provides protection from crevice attack and stress corrosion cracking.

In addition to that, this material has a high chromium content compared to other alloys of the Hastelloy family. Apart from that, this alloy is highly ductile, and it exhibits excellent weldability. Most of the times, it can be easily fabricated on to industrial components. This alloy is available as sheets, strips, billets, bars, wires, pipes, etc. In the chemical process industry, its applications include reactors, heat exchangers and columns. The chemical composition of this alloy is as follows;

- Nickel 56%

- Chromium 22%

- Molybdenum 13%

- Iron 3%

- Tungsten 3%

- Cobalt 2.5%

What is Hastelloy C276?

Hastelloy C276 is also an alloy consisting mainly of nickel, chromium and molybdenum, with comparatively a high amount of chromium than other Hastelloy materials. But the composition of chromium content is lower than that of C22. The chief important characteristic of this material is that it has a proven performance (for about 50 years) in a wide range of aggressive chemicals. Moreover, this material is the first alloy among other alloys of Hastelloy family.

Figure 01: A ball-valve fabricated with Hastelloy C276.

Like other members of Hastelloy family, this alloy is also ductile and has high weldability. It has an exceptional resistance towards stress corrosion cracking. Since it has a high amount of chromium and molybdenum, it can withstand against corrosive chemicals such as oxidizing and non-oxidizing acids. It shows an outstanding resistance towards pitting in the presence of chloride and other halides. Furthermore, it resists stress cracking caused by sulfides as well. In commercial grade, this alloy is available as plates, strips, sheets, billets, bars, wires, pipes, etc. The chemical composition of this material is as follows:

- Nickel 57%

- Chromium 16%

- Molybdenum 16%

- Iron 5%

- Tungsten 4%

- Cobalt 2.5%

What is the Difference Between Hastelloy C22 and C276?

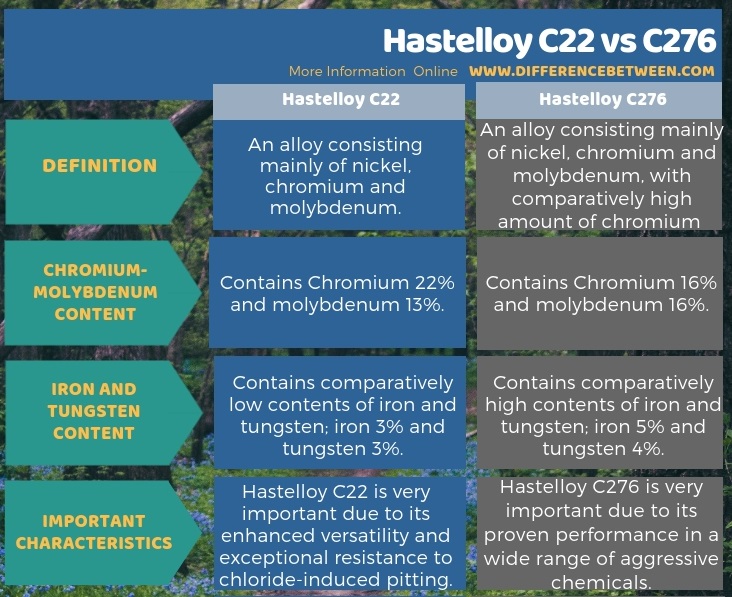

Both Hastelloy C22 and C276 are alloys consisting mainly of nickel, chromium, and molybdenum with a comparatively high amount of chromium than other Hastelloy materials. Therefore, both these are alloy materials consist of several metals but, a notable difference between Hastelloy C22 and C276 is the composition of each metal in the alloy. Because of this difference between Hastelloy C22 and C276, their applications vary in the chemical industry. For example, the Hastelloy C22 is very important due to its enhanced versatility and exceptional resistance to chloride-induced pitting whereas the Hastelloy C276 is very important due to its proven performance in a wide range of aggressive chemicals.

The below infographic presents the difference between Hastelloy C22 and C276 in tabular form.

Summary – Hastelloy C22 vs C276

Hastelloy C22 and C276 are very important alloy materials in the family of Hastelloy. They have different applications in the chemical industry due to their different chemical compositions. The major difference between Hastelloy C22 and C276 is that the Hastelloy C22 is very important due to its enhanced versatility and exceptional resistance to chloride-induced pitting whereas the Hastelloy C276 is very important due to its proven performance in a wide range of aggressive chemicals.

Reference:

1. “Haynes International.” Home. Available here

Image Courtesy:

1.”Válvula de bola en Hastelloy C276, una aleación de níquel, similar al inconel, monel e incoloy..”By JohnLockeLost – Own work, (CC BY-SA 3.0) via Commons Wikimedia

ncG1vNJzZmivp6x7pbXFn5yrnZ6YsqOx07CcnqZemLyue8OinZ%2Bdopq7pLGMm5ytr5Wau260wKyrnqScpMZur5FrZJqmlGKwc4OVaA%3D%3D